Combustion improvement by FEV

At the current stage of development the focus is on the thermodynamic set-up of Neander’s Turbo Diesel outboard. Since midyear 2014 the FEV Group headquartered in Aachen, Germany, is our independent service partner in actual balancing tests and analyses.

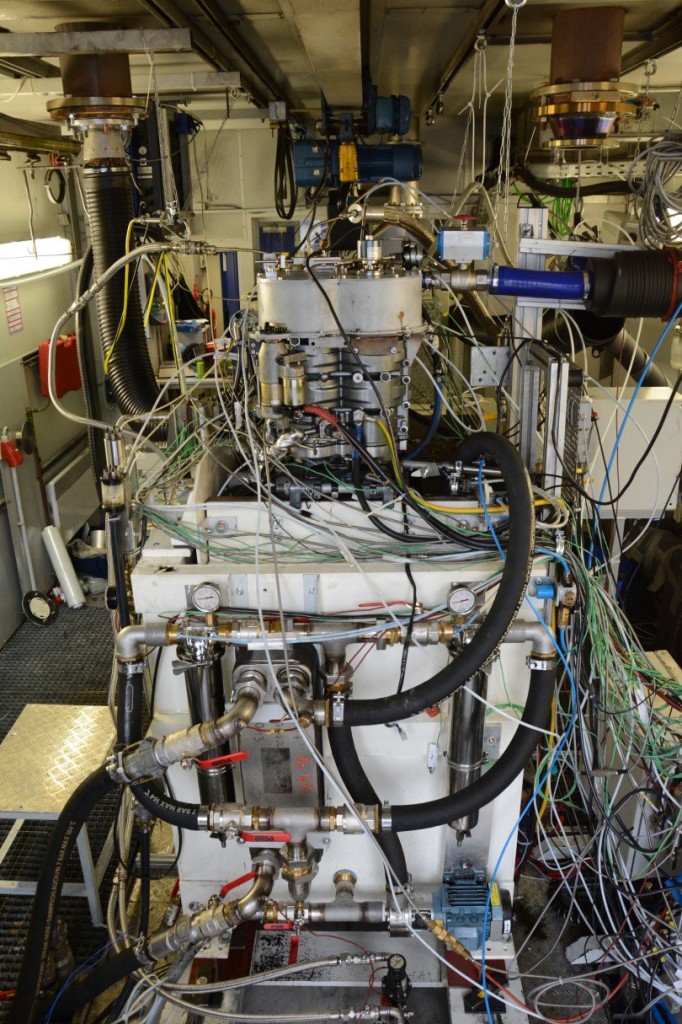

FEV is close-partnered to the RWTH Aachen (Technical University, Aachen, Germany) and its professorship for combustion engines. FEV’s Team for Commercial Engines is responsible for our test bench. Heart of the test device is a water basin on which our motor and its leg are mounted. During operation motor and test bench are connected with various measuring points recording pressures, temperatures and exhaust values. Our aim is to research the motor’s thermodynamic characteristics under specified conditions, e.g. constant water temperature in the basin. In addition pressures (e.g. in the crankcase) and oil and cooling water temperatures are continuously examined.

By simulating various settings we can ultimately optimize consumption and emission of our outboard engine. These settings can be changes of the rail pressure, variations of the start of fuel injection as well as of the nozzle tip protrusion. By means of these modifications and an exact calibration we gain emissions (HC, CO, Nox) and particle emissions beneath the mandatory limit values. By the data we received in Aachen we can create engine operating maps which will provide excellent consumption values and low emissions of our series engines.