TCO

Check our Total Cost of Ownership Calculator

to see how much money you'd save throughout the year

Start TCO Calculator

Dtorque50 Product Training

Order

Our new online shop will go online soon. Until then, please contact us directly via sales@neandermarine.com

Thank you!

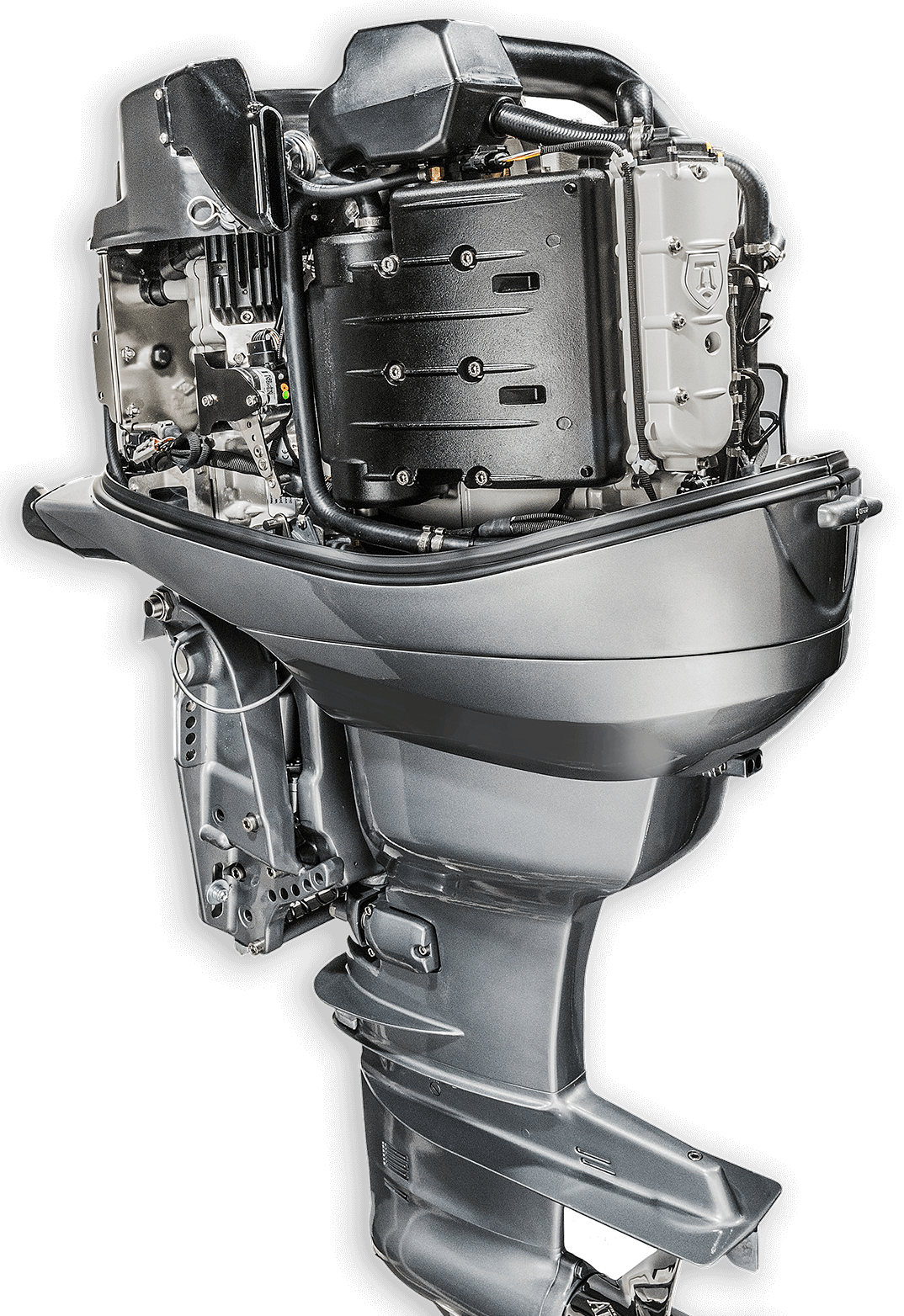

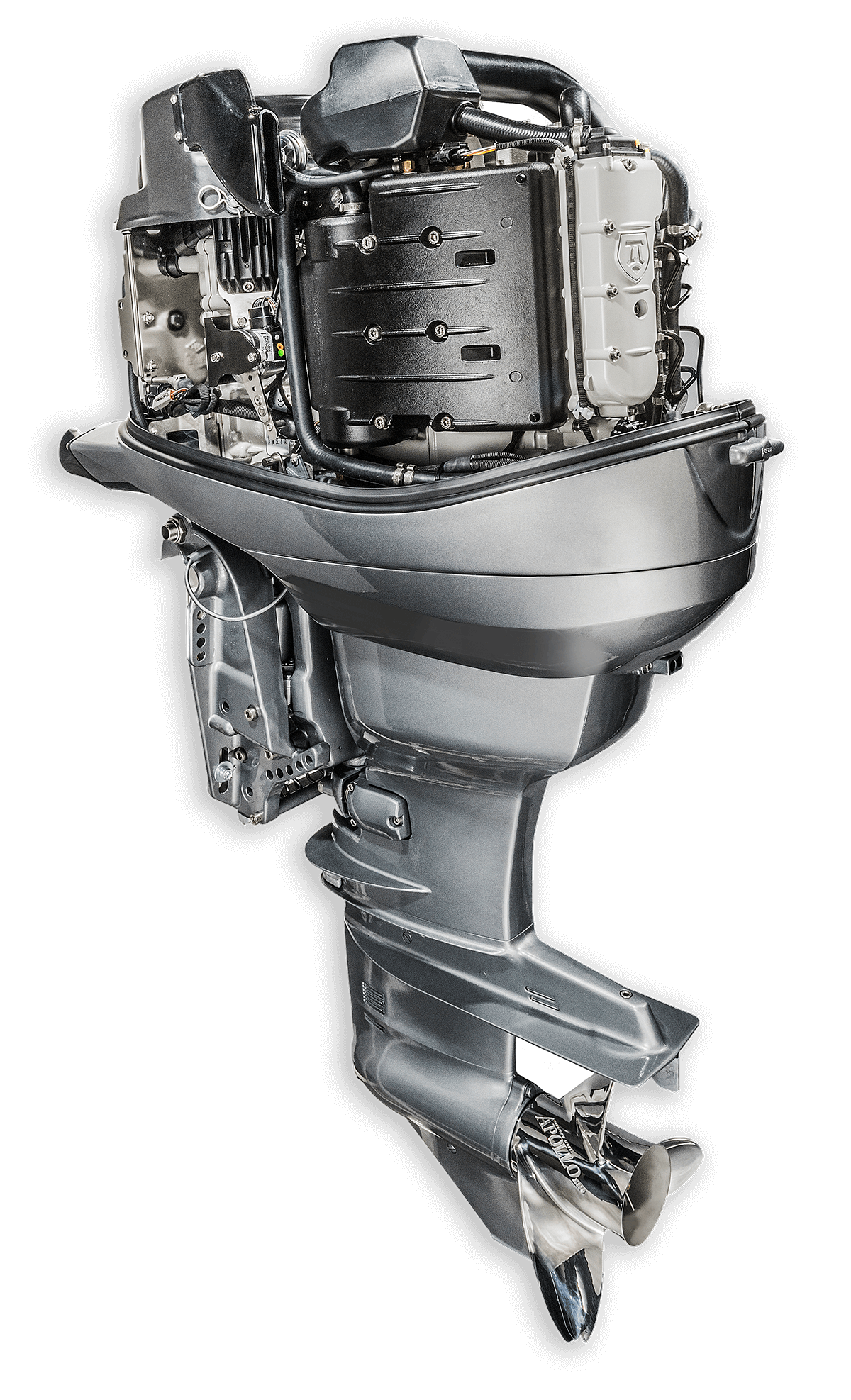

Performance up to 90HP

Why Neander

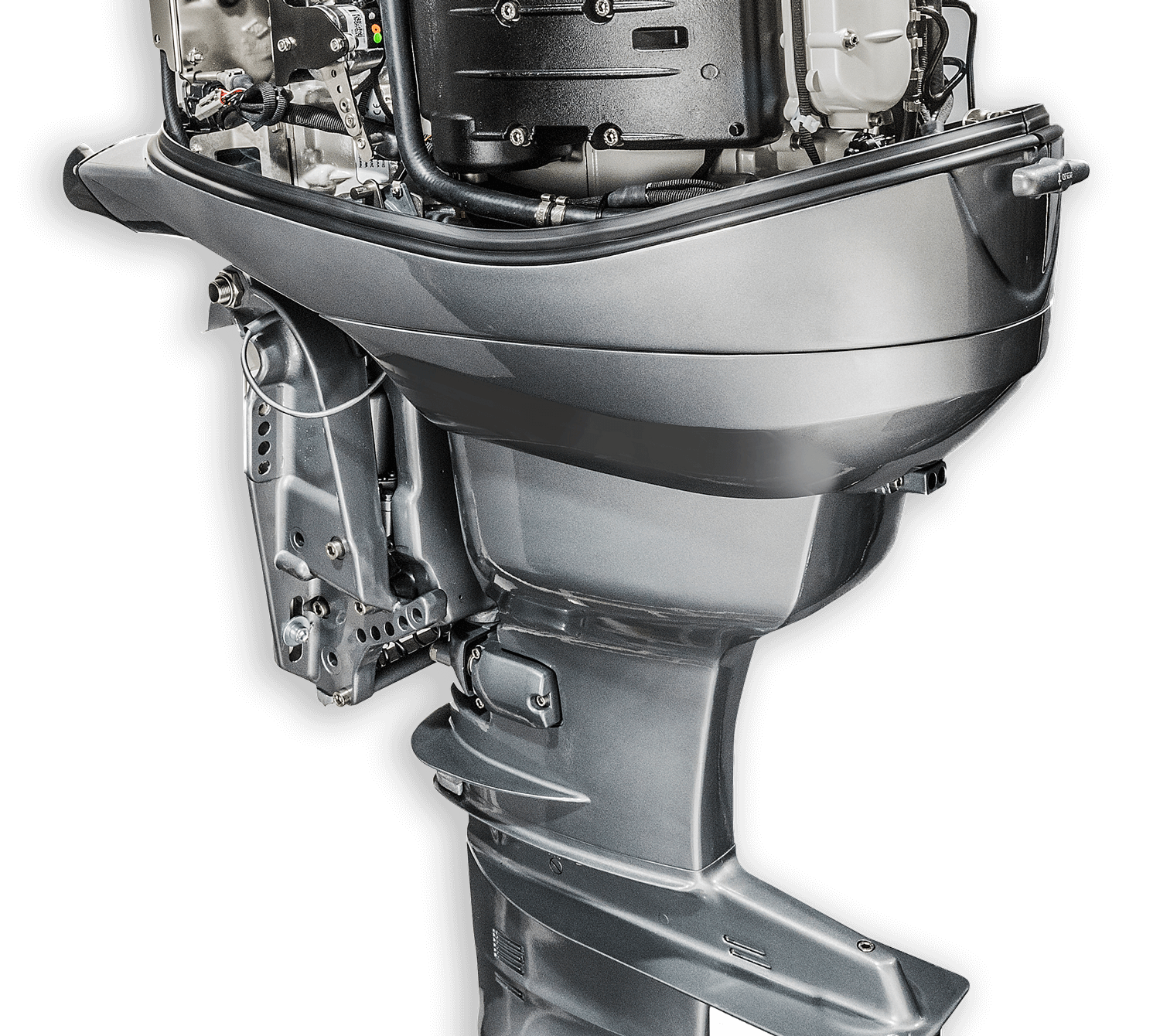

Refined engineering for unrefined environments

The Dtorque has been engineered from scratch, utilising innovative new technologies to deliver optimum performance even in the most challenging environments.

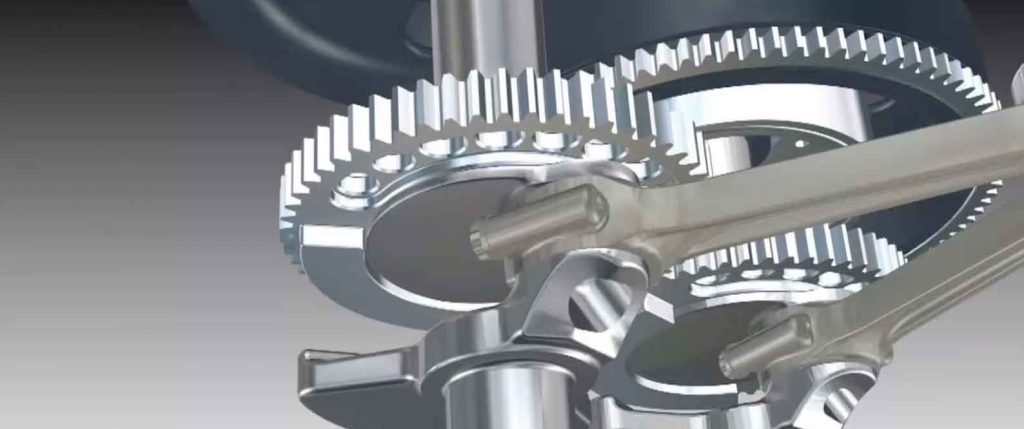

Dual Crankshaft

Dual Crankshaft

Secondary out of balance forces cancelled

Very little torque reaction when using the tiller handle

Creates smooth, quiet and stable engine in all operating conditions

Spaceball Design

Spaceball Design

Force is equally divided over two connecting rods

Prevents forced tilt of piston in the cylinder

Space-ball can rotate in piston bore

Piston pins can also rotate in space ball bores

Reduces unwanted mechanical effects: friction, sticking, scuffing

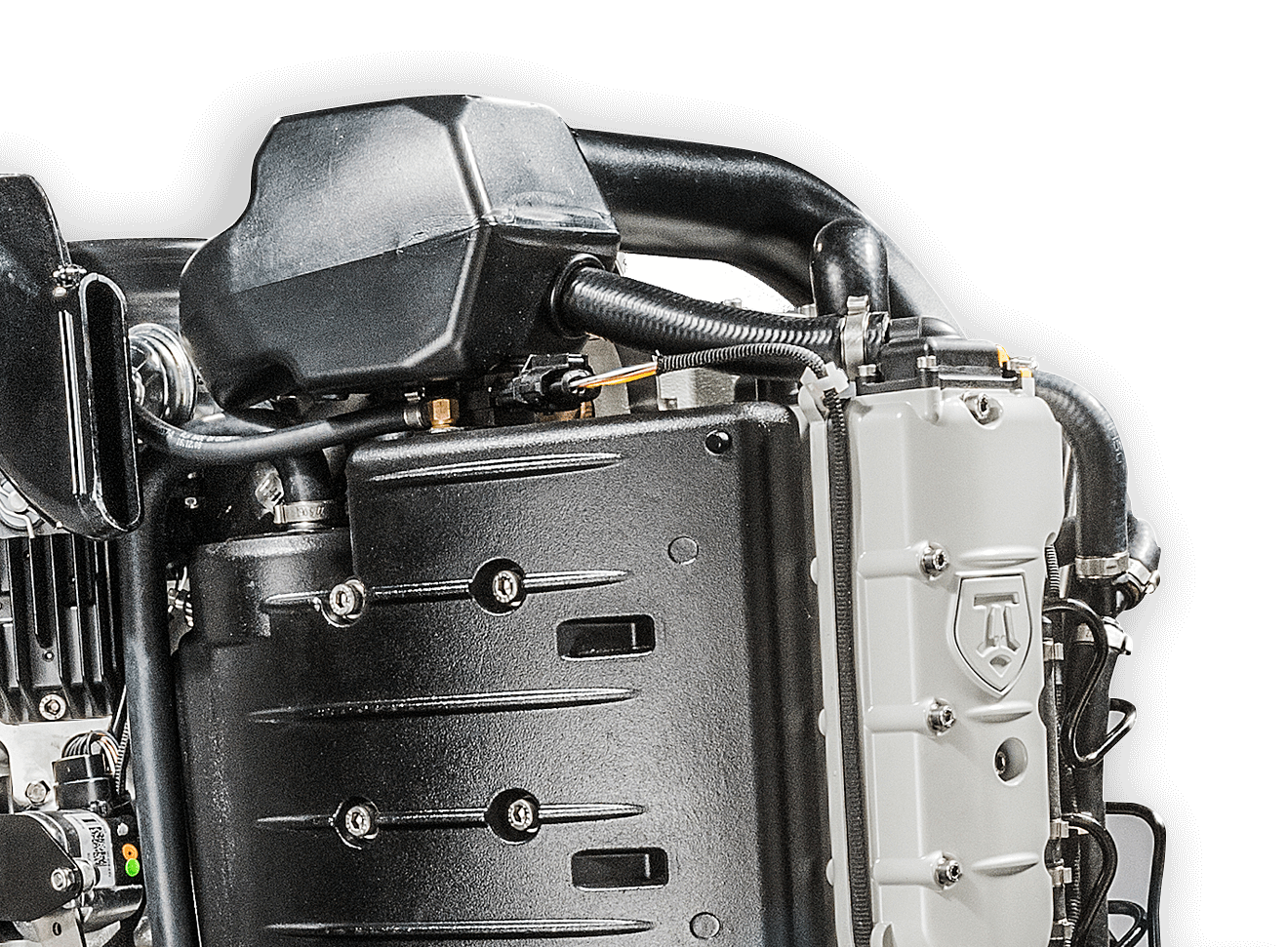

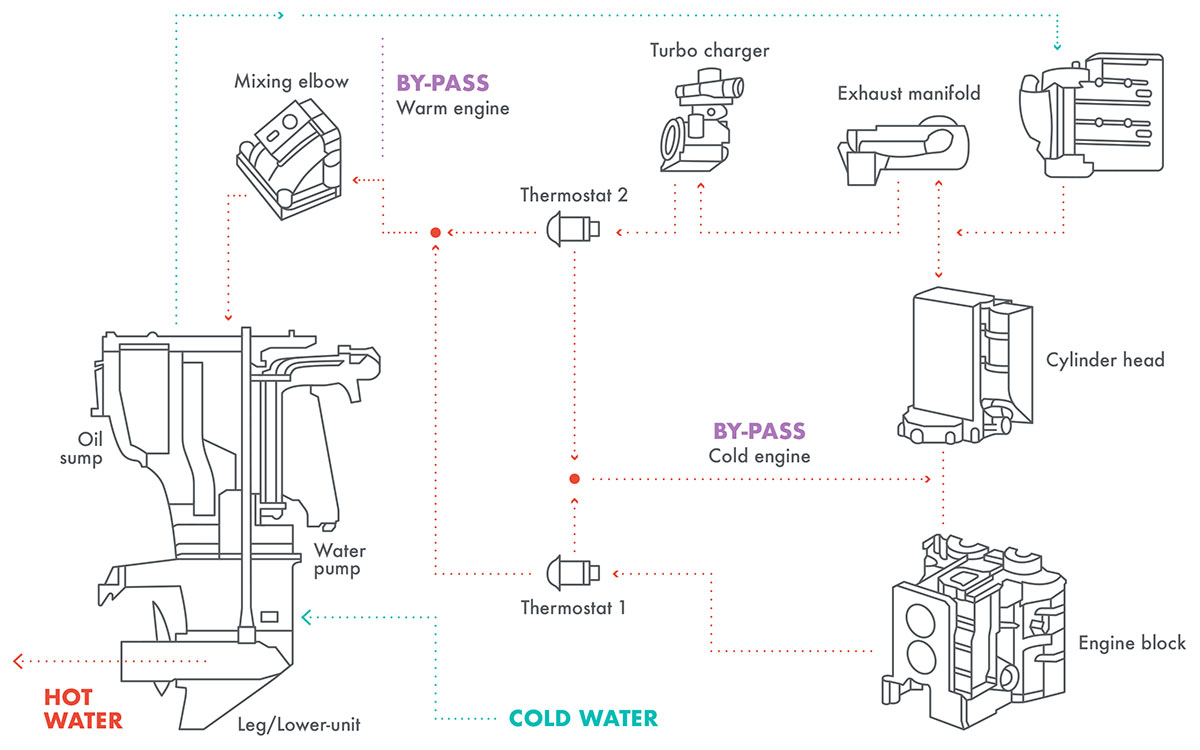

Automatic Thermo-management System

Automatic Thermo-management System

Manages engine temperatures

Reduces risk of overheating

Reduces risk of engine downtime

Aluminium Cylinder Block

Aluminium Cylinder Block

Aluminium design

Cylinder head, block and bedplate joined by long bolts

Optimises durability of structural components

Pressed in cast liners allow rework

Lightweight and strong

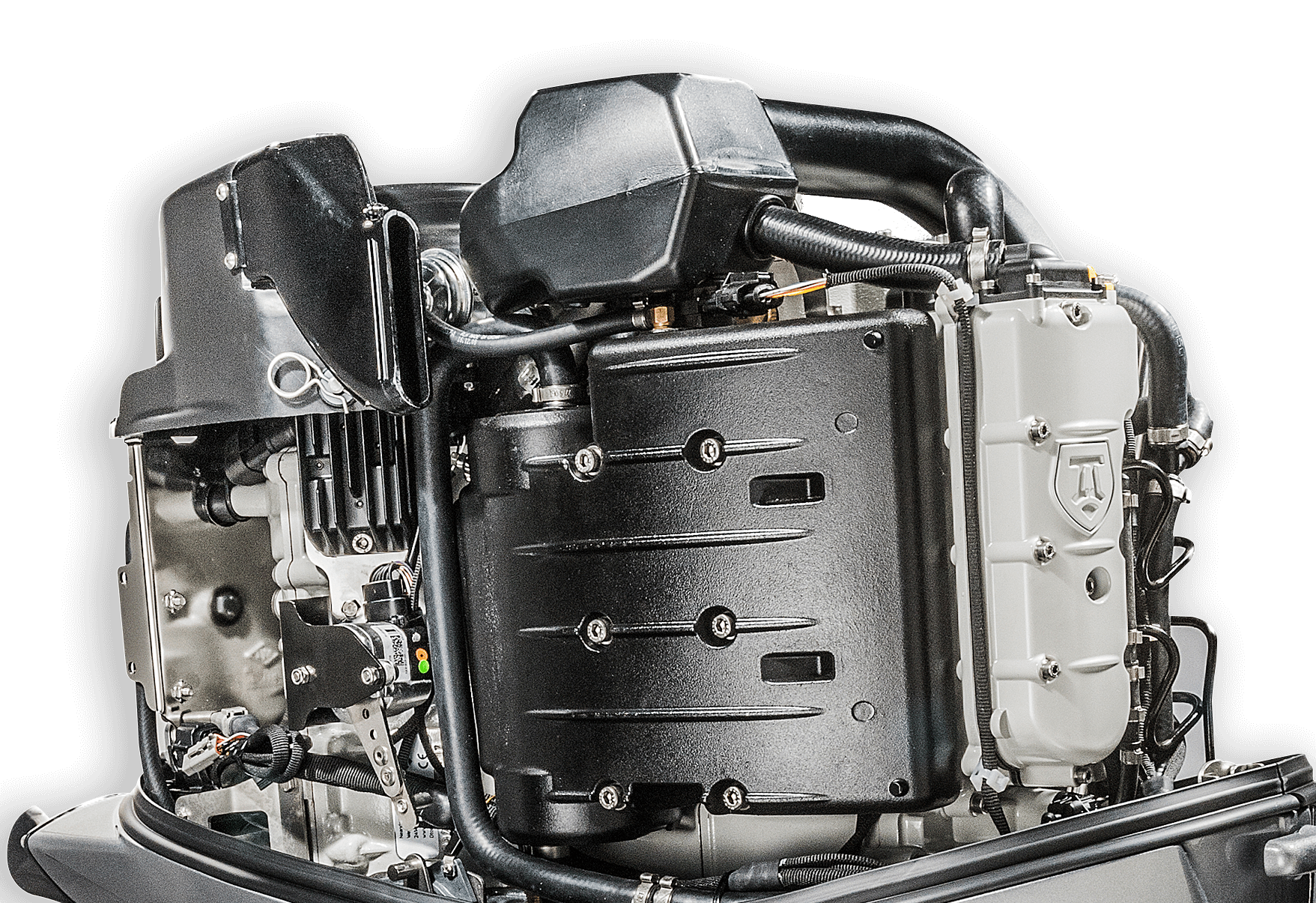

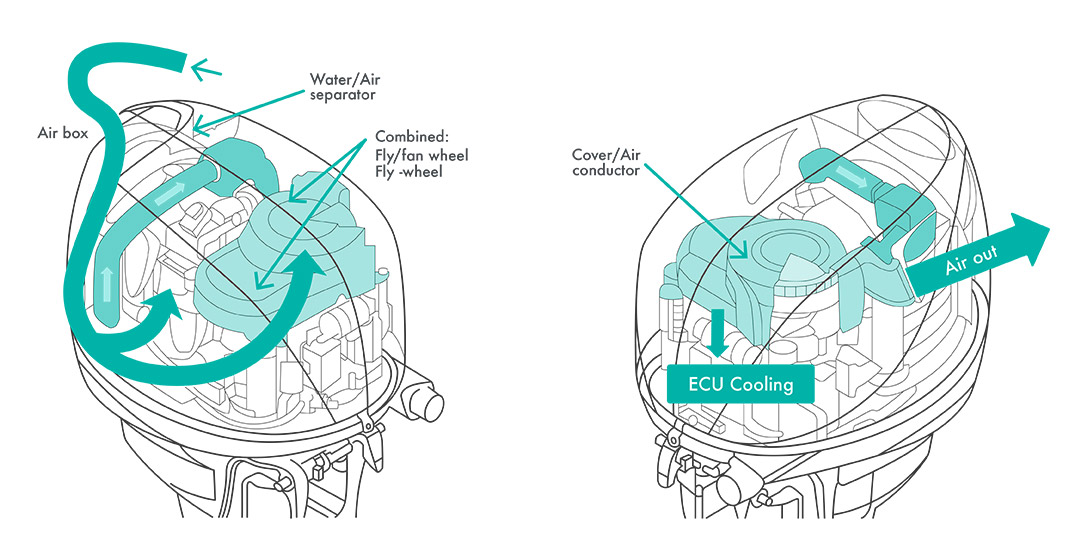

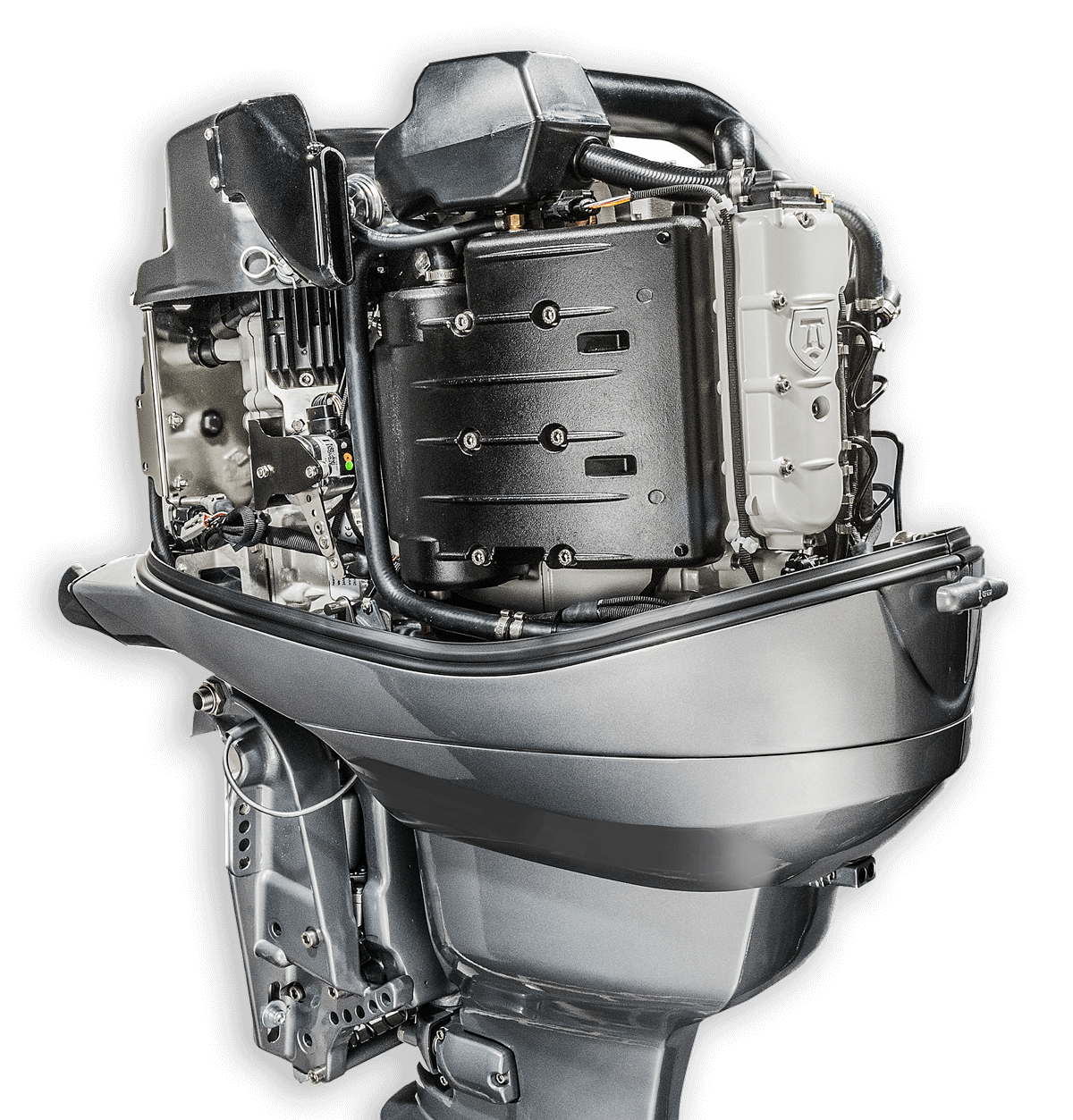

Outboard Cooling System

Outboard Cooling System

Raw – water cooling system

ECU controlled fuelling

Optimised oil cooling process

Oil pan internal fins

Oil pan acts as large heat sink

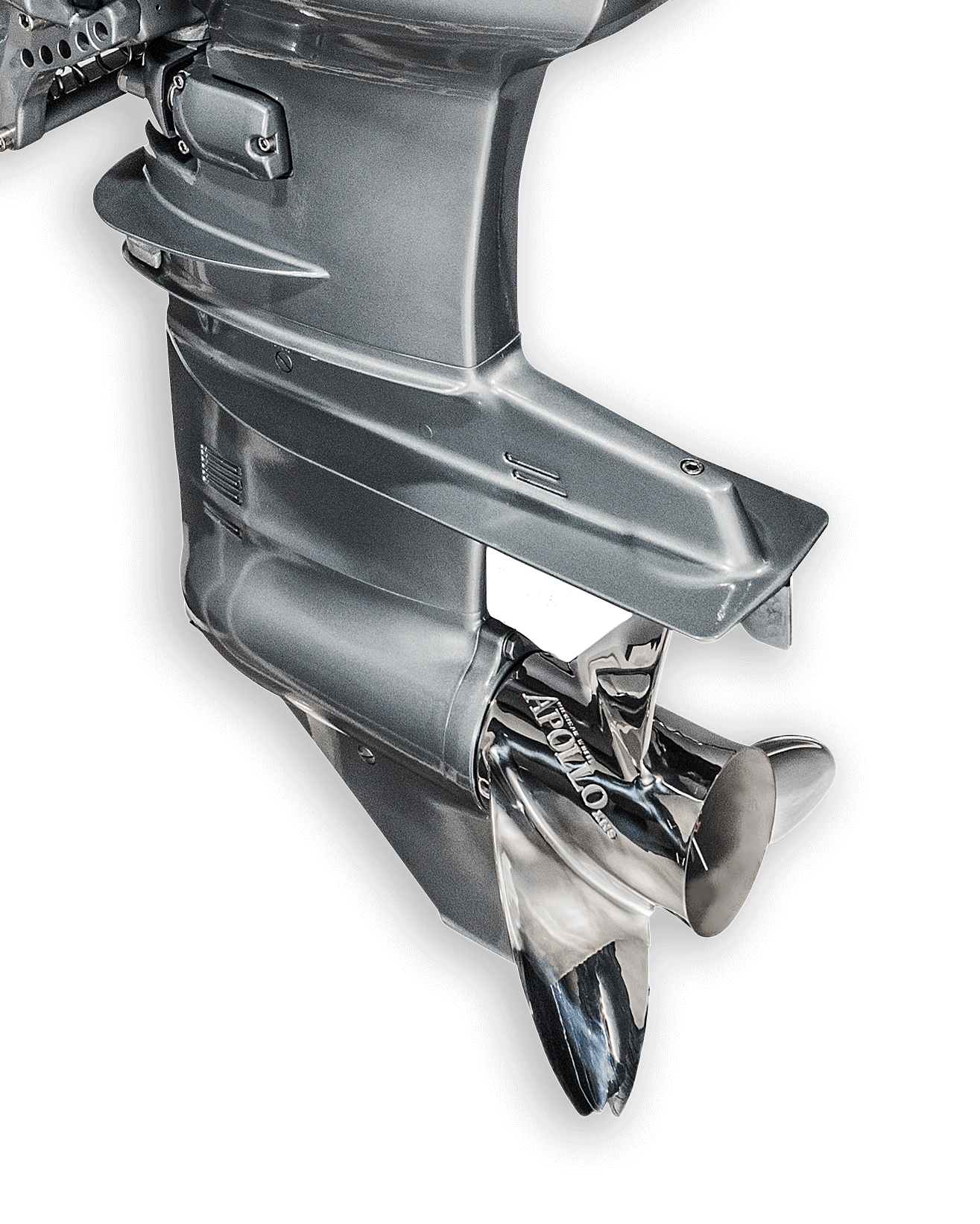

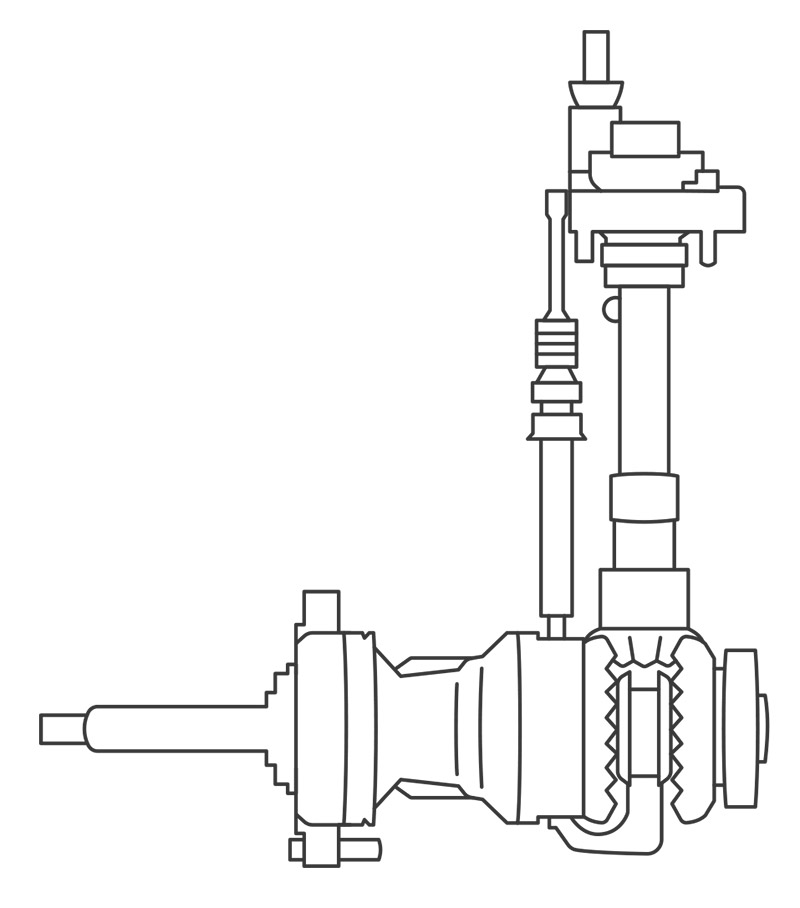

Deep Gear Ratio

Deep Gear Ratio

Lower gear ratio of 2.07:1.

Greater torque at low revs.

Reduced loss of power.

Economical operation.

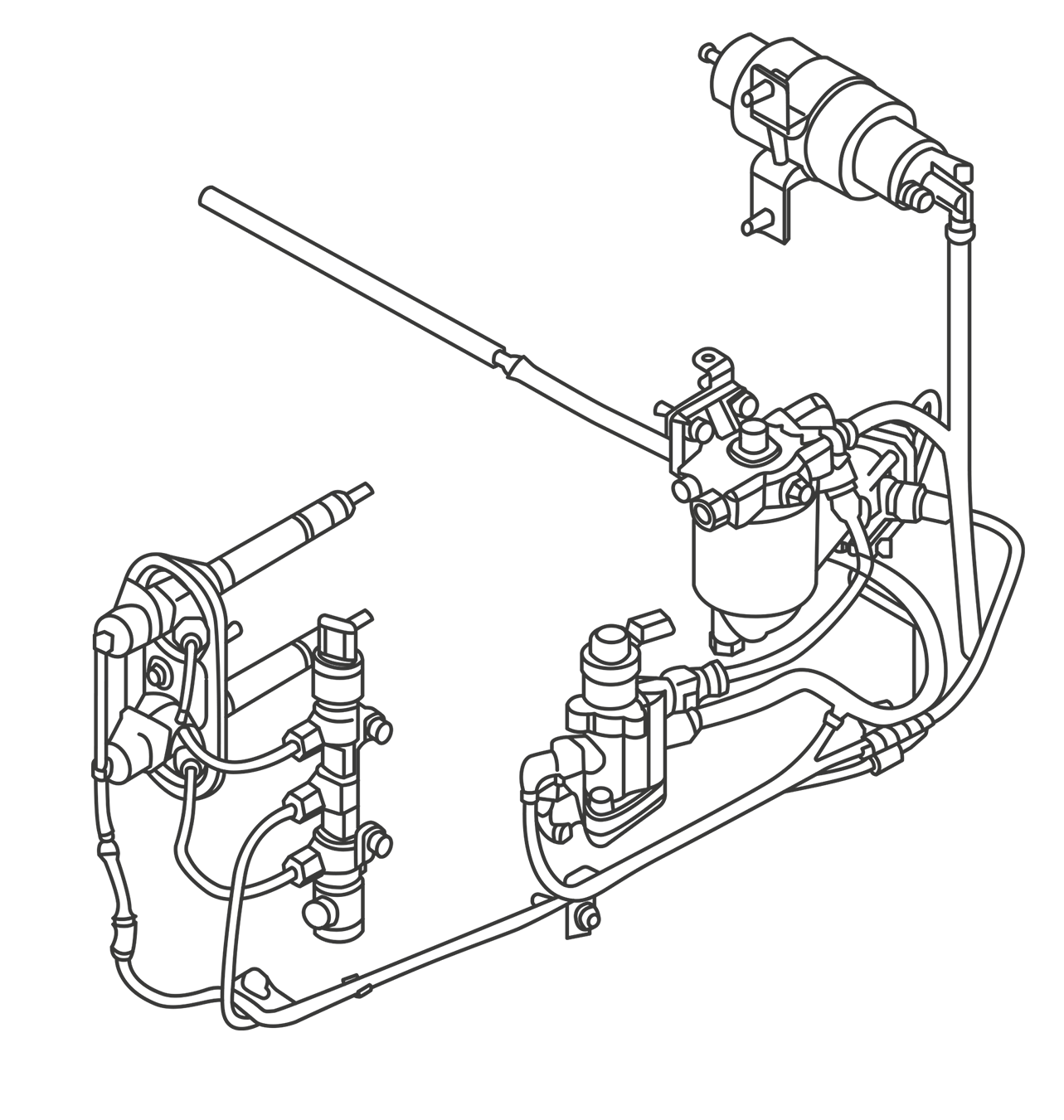

Bosch Common Rail Fuel System

Bosch Common Rail Fuel System

Accurate and repeatable fuel quantity injection.

Delivers greater power and efficiency.

Minimises noise, vibration and smoke.

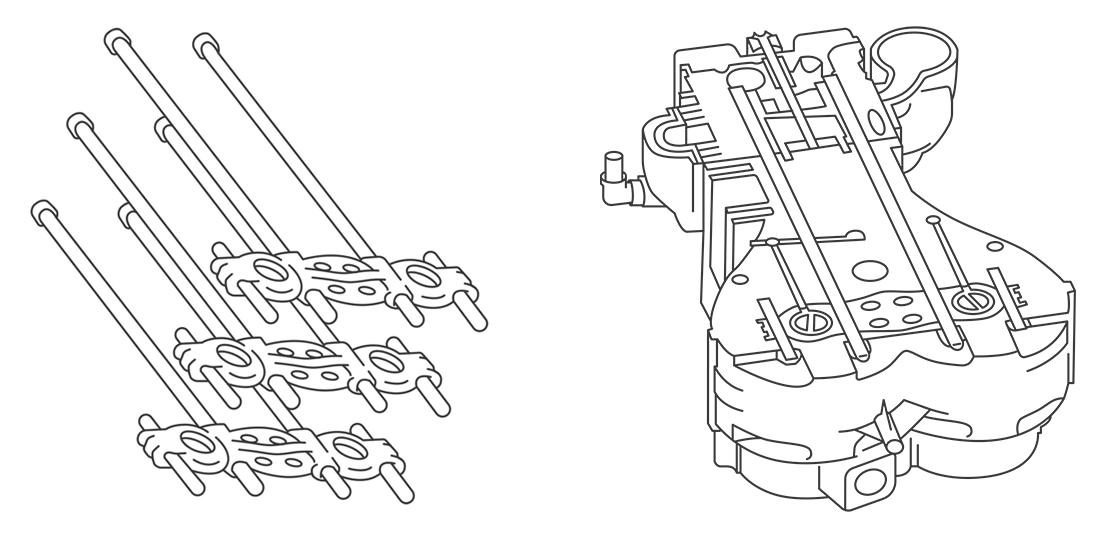

Spaceball Technology

Designed for Smoothness

Two of the key innovations of the Neander Dtorque 50 are the Dual Crankshaft and revolutionary Spaceball Design. By generating opposing forces, the Dual Crankshaft eliminates almost all vibrations and oscillations that would otherwise arise on the control axis, which would make it difficult to use such a small and powerful two-cylinder diesel engine. The advantages for the user are obvious: reduced noise, vibration and odour and greatly improved manouverability.

Full Technical Specifications

Power

36,8 kW/50 hp at 3.500 – 4.000 min-1

Max. Torque

111 Nm at 2250 – 3000 min-1

Engine Type

Turbo-charged parallel twin diesel engine

Balance

Dual counter-rotating crankshafts

Swept Volume

804 ccm

Bore x Stroke

80 x 80 mm

No. Cylinders

2 In-Line, twin

Intake

Water cooled turbo charger and charge air cooling

Lubrication

Pressure lubrication (engine oil Shell Rimula R6 M 10W-40, ACEA specification: E7, E4; at ambient temperatures of < 0 C: Shell Rimula R6 ME 5W-30, ACEA specification: E4, Chevron TX Delo 400 XLE 10W30, Filling quantity max. 6,5 litres)

Fuel

Diesel (Low Sulfur)

Injection

Bosch common rail direct injection

Starting

Electric

Alternator

Standard 12 V/300 W

Cooling

Neander Active Thermo-Management System (ATMS)

Exhaust

Integrated underwater thru-hub propeller

Steering

Tiller / remote control, optional

Suspension

Silent block controlled compression and traction

Trim

Power trim

Shift

Mechanical – dog-clutch gearing

Transmission

Ratio 13/27 (2.07:1)

Available Shaft

Versions 20″ (L) and 25″ (XL)

Standard Propeller Type

3-blade with built in damper

Weight

185kg (dry)

Performance data

Filters

Filters

Application

- Fish Farms

- In-Harbour

- Military & Governmental

- Oil & Gas

- Rescue Boats

- SOLAS

- Superyacht Tenders

- Other

Boat Type

- Aluminium

- Catamaran

- HDPE

- Life Raft

- RIB